High efficiency mixing, cooking, cooling & emulsifying systems

As the partner for Perfinox in the Benelux, Dutch Process Technology (DPT) offers industrial food manufacturers a full range of advanced cooking vessels and complete processing systems — engineered for precision, efficiency, and quality. Whether you're producing sauces, soups, fillings, or emulsions, DPT provides a turnkey solution that integrates seamlessly into your production environment.

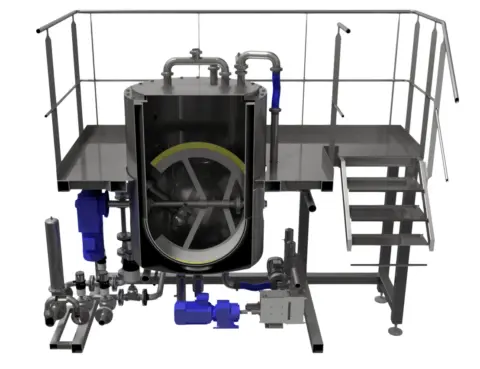

Perfitech all in one systems

The Perfitech system combines various unit operations which makes it a turn key processing plant for a wide range of products. Automatic dosing of liquid ingredients, powder disperions system for dry ingredients and a man way for manual additions. Heating can be done indirectly via a jacket or direct using DSI or Steam Infusion. The bottom driven agitator design ensures gentle mixing and if needed an inline high shear mixer can be used for size reduction or creating an emulsified product like mayoniasse. The entire system is CIP cleanable ensuring a repeatable validated cleaning process.

Perficooker cook & fry

Designed for maximum thermal efficiency, this vessel features a double heating jacket, offering superior heat transfer and consistent temperature control. Ideal for dense or sensitive formulations, it ensures gentle product handling and supports integration with automated dosing, mixing, and cleaning systems.

Tiltable vessels

Perfect for mixing, heating and cooling smaller batches of product. Vessels can be emptied by tilting the vessels or via a bottom discharge valve.

Fat melting systems

Ergonomic and safe systems for melting blocks of fat. Operators can easily unpack blocks of fat and slide them onto the melting grid. The temperature of the melted fat inside the vessel is controled via heated double jacket in the vessels bottom. Optionally the system can be equiped with automatic dosing towards the next step in the production process.