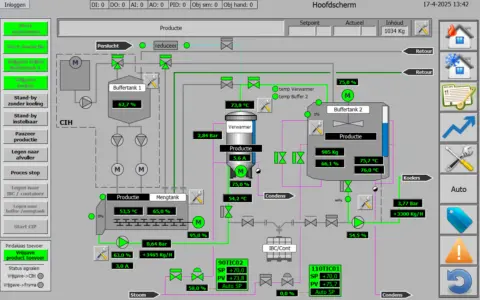

Food factory automation

InProServe offers a wide range of services: electrical drives, control / automation systems, servo drives, service and repair. Inproserve designs, installs, commissions, and supports industrial process automation systems. We focus on programming (PLC/HMI/SCADA), as well as designing and building control cabinets, etc. Typical processes that we automate include:

Pasteurisation / Spray drying / Dosing batch & inline / Mixinig batch & inline / Aseptic conditions / CIP & SIP / Recipe management

Engineering:

Designing, programming, testing, and commissioning process control and process visualization software. Our engineering department can assist you in many ways with the realization of your project.

Software engineering:

Over the years, we have gained extensive experience with various PLC systems and fieldbuses. Some common systems include:

- PLCs: Siemens, Allen Bradley, Mitsubishi, Unitronics, etc.

- HMI touchscreens: Siemens, Allen Bradley

- SCADA: Siemens WinCC, Ignition, Cimplicity

- Networks: Profinet, Ethernet-ip, Profibus-DP, MPI, etc.

Hardware engineering:

We draw up the main circuit and control diagrams and design control cabinets using WS-CAD and AutoCAD, among other software. We also take care of your complete technical documentation.