Heat, mix and pump with Steam Infusion

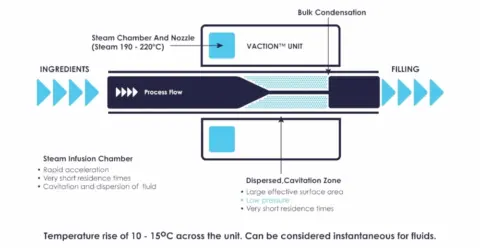

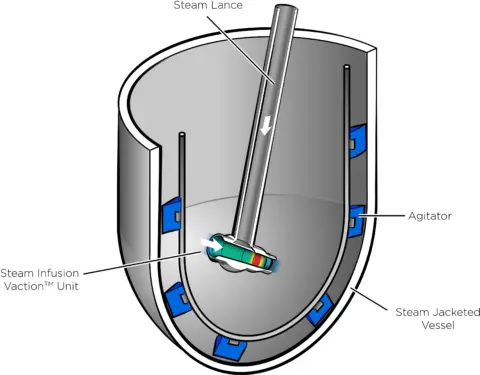

Steam Infusion is a direct contact heating process whereby steam condenses on the surface of a liquid, gently yet rapidly cooking a range of food and beverages up to a temperature of 140°C. The patented Steam Infusion Vaction™ Pump rapidly heats, mixes and pumps food ingredients and products. By varying the steam pressure and flow rate through the pump, the processing conditions change, from gentle cooking to intense mixing and pumping with a homogenising effect.

What is Steam Infusion?

Like jet cook, Steam Infusion is a form of steam injection, however the patented design of the Steam Infusion Vaction™ Pump uniquely introduces steam, achieving a wider operating envelope and delivering a number of processing improvements, namely:

- Elimination of burn-on or Maillard reactions

- Processing of particulates up to 20mm (0.79in)

- A controllable shearing effect

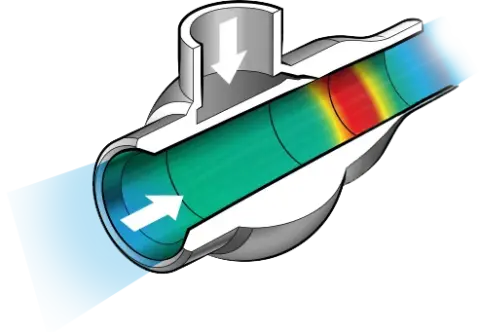

Steam Infusion uses steam as the motive force but thanks to the geometry of the pump, it can heat, mix and pump liquids with and without particulates. Steam is introduced into any liquid via the patented Steam Infusion Vaction™ pump, in which the profiling accelerates the velocity of the steam to 1,000m/s (3280 ft/s) – above the speed of sound. The steam passes into the mixing chamber through an annular nozzle disrupting the fluid flow to form small droplets, referred to as the vapour phase. The momentum transfers from the steam to the product and creates a partial vacuum of -0.7barg (-10.1psig) within the unit and, depending on the configuration of the engineered system and the needs of the application, can also reach temperatures of 145°C (293°F). Despite the high temperatures, no burn-on is left on the product and there is no presence of syneresis when used at temperatures below 100°C (212°F).

Increase cooking capacity

Unlock high speed cooking and make more product within a smaller footprint. With Steam Infusion you can cook 1 000kg of particulate product in less than 10 minutes while cutting CIP requirements by

50% thanks to the prevention of burn-on.

Energy efficient

Steam Infusion achieves highly efficient energy transfer, with less than 3% energy loss In-Tank and In-Line. The annular design of the Vaction Pump allows steam to condense within the Pump itself and the heating process does not rely on contact time between the steam and the product so it can run at comparatively higher steam pressures without compromising on efficiency, minimising losses to the atmosphere. Our research has shown that you can achieve up to 20% reduction in energy consumed when using the Steam Infusion system compared with traditional steam-jacketed cooking vessels, depending on your existing processing conditions. This can help to both reduce costs and boost your green credentials.

Develop new products

Create healthy new products and reformulations by utilising the Steam Infusion processing environment to enhance and retain flavours and colours. Over 10,260,300kg of product processed every day using Steam Infusion. Steam Infusion achieves repeatable cooking time and time again, whether you choose batch or continuous processing. An inherently controllable technology, it can be adapted to meet your recipe needs, delivering end products that will delight your customers.